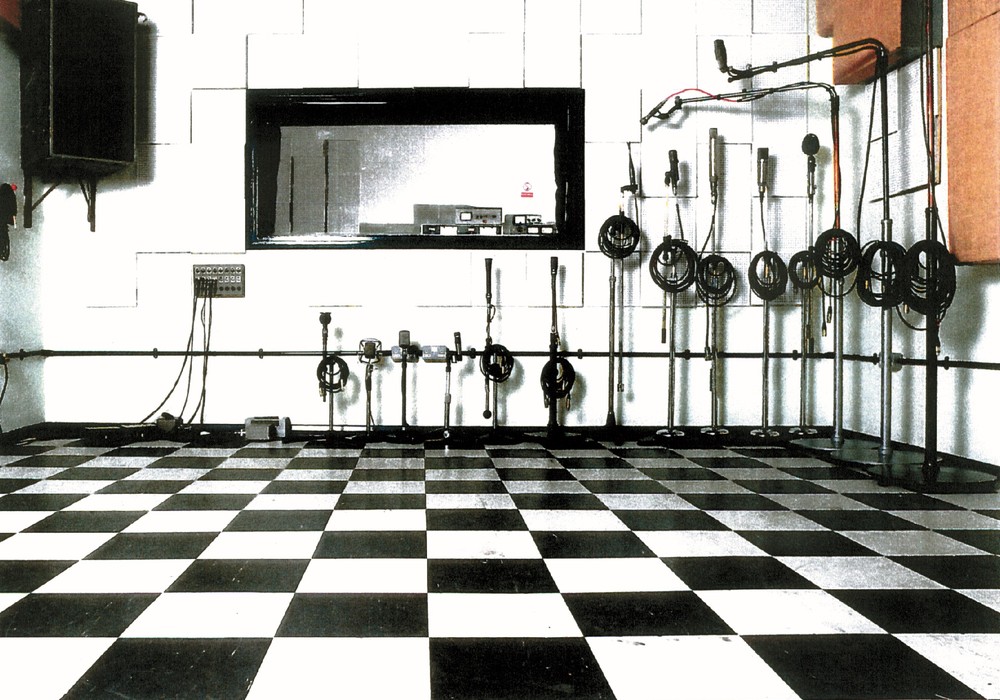

Under the leadership and vision of EveAnna Manley, Manley Labs has created and built some of the finest studio equipment (and high end home audio components) over the last two decades. Studios across the world count on their mostly tube-based EQs, compressors, microphones, preamps, mixers, and more.

The first piece of Manley gear my studio had was one of the older one-channel compressors, like a Vari-Mu style I think.

Was it the one and a half-U chassis?

It was. Elliott Smith bought it. I had to call you one time to get the tubes replaced. I got you on the phone, which blew my mind. We sent it down and it came back working better.

These days Paul Fargo does our tech support out of Arizona. He does all the tech support and repairs, assisted by Gamma Ibarra and the factory, but I'm also part of that team as well. When you call and you've got questions about something with Manley, you'll get Paul, Gamma, or me on the phone easily. That's no problem.

Back then I thought companies would be so big, where you can't get ahold of anyone who knows anything. I learned a lot more about the biz as I started the magazine. People are passionate about what they're doing. It's different.

We want to take care of the customers. You don't want people upset on the Internet writing nasty things about you. We try to take care of people as best as we can. You've got to balance that with business decisions as well. We've got a reputation for great customer service, and I know that sells a lot of gear for us. I'm not stupid, right? This is analog electronics, so it's not always going to be 100 percent perfect either. Also, imperfection is what contributes to that sound, too. Let's talk about vinyl records. If you want to measure vinyl records with your crosstalk and tracking distortions and frequency response. Vinyl has all these technical, terrible imperfections, but it sounds pleasing. People like the way it sounds. That's another thing with analog gear. I think all the people mixing with their eyeballs need to go back, relax, listen with their ears, and allow analog to do its thing. Sometimes it is those imperfections or those slight mismatches that gives things that sound. If you take all the imperfections out, remove all the distortions, take all the errors out, then you have a mathematical model. You have a plug-in that's technically perfect. But does it sound good? Does it make the hairs on your arms stand up? That's the thing. I use that as a test when we're designing transformers or something like that. It's a balance between what you measure and see in the oscilloscope versus what you listen to. You might go back and decrease something to let it saturate. Technically when you measure it again, it's not as good, but when you listen it sounds great. The hairs on your arms stand up, and you start wanting to dance and be involved with the music. That's the art of what I do. What I like to look for in design is to try to relate technical stuff, measurements and all that, with vibe, feel, and what's emotionally able to get you going. That's the magic, the secret sauce right there.

Nobody buys the gear because it's boring, or just because it just gets the job done.

Well, sometimes you'd think they do, with those comments! I think they're getting too hung up on computer plug-in perfection maybe. They've got to mix with their ears, not with their eyes.

Are there new products coming out?

We do have a new product coming out. CORE. It's a new channel strip for half the cost of the VOXBOX, with tubes and a transformer. In the past, when we've designed things, we always said, "Let's do this. Okay." Or "Let's add this feature," or "Let's use that capacitor," or "Let's put two of them in! That'll be awesome!" Then we add up the cost and it's like oh hell, it's going to retail for $6,600. These days, we did this with a hi-fi product, the Chinook, which is a baby phono stage to the big Steelhead, so it's a quarter the cost of the big one. We had to retail it for around $2,000, so every part got scrutinized, every bit of the circuit. We shaved off all the front panel controls and made it very simple. That made it a little more cumbersome to operate, like setting the loading and stuff, but the features are there. It's designed to set and forget. All the engineering we did for that, you could call it cost engineering, but it really made the design more efficient in all ways and much faster to build. We did things like swapping out servos for trim pots and things to save time. The design got clever by trying to simplify it for cost purposes. In many ways, it's a more advanced design than the Steelhead. That's kind of exciting, because you think of more effective and efficient ways to build the gear. This new channel strip we're working on is like a baby VOXBOX. The mic pre and compressor section's pretty much like the VOXBOX, and then you've got a solid-state EQ with a sweepable-mid in shelves, and a final, real fast peak limiter (FET limiter, brick-wall limiter). There are quite a few knobs on the unit. It's pretty flexible, but it's directed toward the musician who's not a recording engineer. It's for somebody who gets called by an engineer saying, "Hey, I need you to fly in some bongos from home." So for the bongo player at home, if it's too complicated or there's too wide a range, he'll set it wrong and get it all distorted. We're trying to make this box very simple so that a musician like that can just set it up, get the take, and concentrate on the music instead of fiddling with knobs, which is something he's not really even interested in. We're on prototype number two right now. We're re-laying out the board right now and cleaning up some things, and then we're going into prototype number three.

Do you send them around to some engineers you know and trust and try to get some feedback?

Oh yeah. That's what's great about being in LA. You've got all these people. The last beta tester I used on this unit was Rafa Sardina. He knew the problem so well, because he's the guy calling the bongo player from across the world to play. He's always on the phone with these guys asking them, "Where did you set the output control?" He's trying to remote control help and engineer from afar. It's for a guy like this that we need the Manley CORE. My husband Dave Collins has done up the design for it. He's the chief designer for this one, working with our team in the factory. It's great. Dave's super-clever, super-critical, and he's primarily a mastering engineer. He's very fussy and a very good critic of our products. He's always going through our stuff and saying, "What moron did this like that? Who does things like that?" I'm like, I don't know. It's been like that from day one. But now that you mention it, that is really idiotic. Why are we still doing it that way? We're always critical of our own work.

When you think about tube gear, a lot of people wouldn't know about how to drop in new tubes if you have to do any kind of biasing, or really spec it and make sure it's right. They want to know that they can just send it back.

Well sure. And they're not going to read the manual. We've established that. No, that's fine. We try to make the gear as easy to use as possible, and the circuit's not so high-strung that you need all this adjustment. The other thing that I always like to talk about these days is that there's a difference in what people expect from their gear. Take that Variable Mu you had. At a time in the early '90s, we had that one and a half-U version. You could get two of them and link them for stereo, but at no time did we ever match two units together to make a quote "stereo pair." But if you were using it, there was linking facility in the back. You could link them together, and that would link the sidechains to get them to sort of track. But you still had to set up both inputs, and you had to set both releases the same. I think that yours might not have had an attack control?

I don't think it did.

Unless we had added it later.

It was really simple.

You had to set everything up pretty much the same. And guess what? You had to listen to what you were doing and make sure that you were right on center. Because the one unit in no way had anything to do with the second one that you bought a year later. They had nothing to do with each other, so you had to line them up with your ears and listen to it. In the old days with the stereo units, we just sent them out. But as time went on, people started to say, "You know, when I set all the knobs at midnight, one channel is 1 dB louder than the other one." We're like, "Okay, just knock that output knob a little bit. No problem."

People don't even understand the carbon on the potentiometer is never even quite the same.

Well, we use conductive plastic...

You know what I mean!

But when you're dealing with a stereo input pot, the wipers will just track left and right, and that part is specified at a twenty percent tolerance.

In the audio realm, that's pretty terrifying.

It's a lot. We built a little jig with a computer program in QBasic that showed a graphic display of the dB tracking error of the two sections, so we were grading the pots and selecting for 1.5 dB at the time. The calls kept coming in, so we selected for 1 dB, and then 3/4 dB. Then we're taking the sections apart and measuring all the front sections and all the back sections, and entering that all into a database and hitting a button. It would calculate the curves of the sections, and then it'd say, "Yeah, front section #52 is a good match for the back section #298." Then you'd reassemble those two as mates. Then guys were like, "No, it's a half dB off. I want a new unit." Finally, I just said F-it, we'll just put a switch with resistors in there. Then guys are like, "Oh, but I want the pot version!" Then I put it all together, and I was like, "I get it now. Guys are relying too much on the meters on their screens, and they're really not listening." By definition, you can hear a difference of 1 dB, right?

Yeah, hopefully.

Hopefully you really do hear a dB, but a lot of people can't really hear a half dB, so when they're criticizing us when they measure a 0.2 dB discrepancy, it's like, "Dude, you can't even hear that!" They're expecting plug-in accuracy from analog equipment, and that's very difficult to do without extensive measuring and matching of everything. You can only do so much versus cost. It's no problem. We'll do it, but how much would you like to pay? It gets to a point where you can't do it.

Yeah, stop looking at those meters.

Stop mixing with your eyeballs. That's my message these days. I'd like people to go back to mixing and recording with their ears. That's what it's supposed to be.

I think a lot of your gear is designed very tactile, in my experience of using it.

Coupled with good ergonomics, too. With the VOXBOX, when I first sketched out the shape for the panel design (to me at least visually) with the shapes, you'd memorize the shapes more than just seeing a whole grid of knobs on the faceplate where you have to memorize that some knob is four over and two down or whatever. For my hand, the shapes helped the eye-hand relationship. If I'm going for that knob, I know exactly where to go innately. It doesn't take a lot of brainpower to memorize where that attack knob is or something. You go for it really fast. That tactile feel coupled with ergonomics is what I'm always going for.