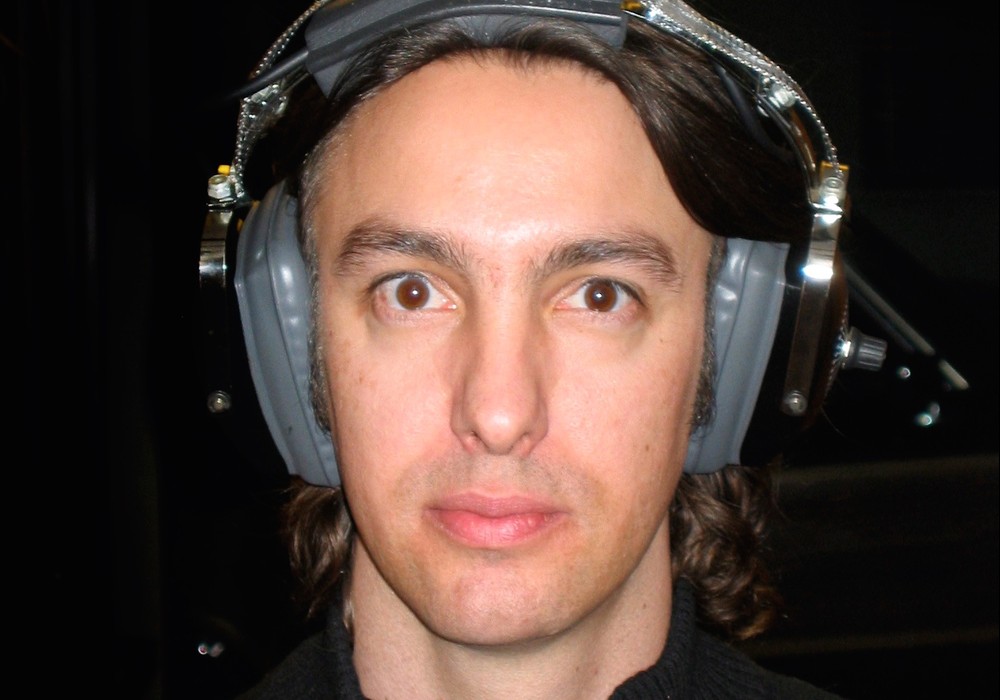

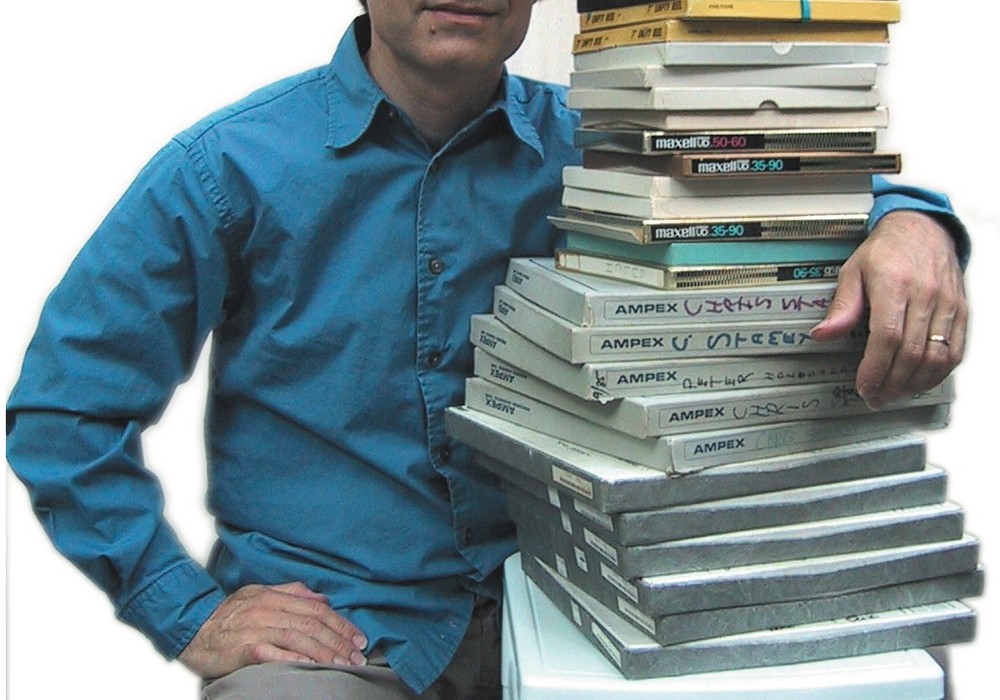

Made up of former AKG employees, Austrian Audio is a new company located in Vienna. I sat down with Kent Iverson, Head of Marketing and PR (former AKG Director of Marketing and Product Management), and Christoph Frank, Senior Acoustics Engineer (also formerly of AKG), to discuss the plans for this new company.

How was Austrian Audio started?

Kent Iverson: The company was founded by 23 former AKG employees, with three of the former directors, including Director of Engineering, Director of Product Management and Marketing, and Director of Sales, who is also our CEO. In 2016 it was announced that Harman was being acquired by Samsung, and that officially transpired around the beginning of 2018. Samsung/Harman gave all of the AKG professional employees notice that their positions would be eliminated and that manufacturing was being moved out of Austria. Ironically, there had been some discussion in the halls of AKG for some time about possibly forming our own company. Many of the engineers felt that they were largely doing maintenance engineering and there was not enough corporate-level interest in allowing them to try new ideas. Now with our own company, our engineering team is free to pursue their ideas.

What do you mean by "maintenance engineering"?

KI: Things like introducing a new version of an existing product or working on ways to lower the production cost of an existing product.

Where has manufacturing of AKG products been moved to?

KI: Some things have been moved to Eastern Europe, and anything that could possibly be made in the Far East has been moved there. Some of the manufacturing equipment is very specialized. For example, when the AKG K812 headphones were being manufactured in Vienna, we made the diaphragms for them here. Headphone diaphragms can be very complicated. They are not simply a flat membrane, and can have varying density as part of the design. No one sells a diaphragm stamper, heat treater, or anything like that, so some of the machines on the factory floor were completely designed and built by our in-house engineers.

Was Austrian Audio able to acquire some of this equipment from AKG?

KI: We did a deal with AKG where we bought as much as we could – everything from office furniture to machinery. In fact, some people are still using the same desk that they had with AKG! But Samsung/Harman took some machinery to the new manufacturing locations, including the K812 diaphragm stamper that I mentioned.

Had the introduction of lower-cost condenser microphones in recent years put financial pressure on AKG?

KI: It depends on the product line. I would consider anything that descended from the original AKG capsule to be the best-in-class at what it does. The lower cost condenser mics are usually built around outsourced capsules. Just a few manufacturers make the capsules and then various companies will design electronics to go with them. The AKG 414 capsules were always made here in Vienna, and employees were usually not promoted to working on capsules until they had been with the company for ten years or so. When AKG introduced the lower-priced Perception series, they did use some of these third-party capsules in order to keep the cost down. But AKG had enough purchasing power to sometimes help these manufacturers improve their manufacturing processes. So the lower priced models often had AKG technology and tuning in them even though they were not an AKG capsule.

How are the third-party capsules produced at lower cost?

Christoph Frank: High-end capsules are produced one at a time and diaphragm tension is carefully controlled. The outsourced capsule manufacturers usually tension an entire sheet of gold-sputtered mylar and then mount the diaphragms for twenty-five or more capsules simultaneously, so the diaphragm tension is less uniform.

What products are in the works?

KI: Our first product, "Aurora," is an analyzing test and measurement software/hardware suite for manufacturers in the audio industry. It offers a customized hardware solution in the form of sensor inputs into a computer running proprietary software. Aurora is intended primarily for high volume production-line testing of acoustic components like transducers, as well as circuit boards and completely finished and assembled products. If there is an electrical signal, our system can test for it and assure quality of AC, DC, RF, frequency response, THD, and other parameters on an assembly line and it all occurs automatically and without the need for a highly-skilled operator. The first hardware product will be a large-diaphragm condenser microphone with a lot of interesting features that I cannot reveal at this time.

A large dual-diaphragm condenser is exactly what I would expect from former AKG engineers.

CF: Certainly that is AKG's legacy. But while AKG had a long and wonderful tradition, a tradition can also become a cage. You will see a lot of new ideas in our new microphone that would not have been possible under the umbrella of AKG. It will resemble the best of what AKG did in terms of sound, but it will also incorporate some very unique usability features that have not been seen before in a microphone. It will almost be three microphones in one.

So the new microphone may have more switches than the 414?

CF: Actually it will have fewer switches, but you can do more with it! But it is still a traditional true-condenser microphone. Everything is pure analog – we are not using any DSP or anything like that.

Tell us about your new capsule and how it relates to the legendary CK 12 brass ring capsule.

CF: Ours will be a very traditional capsule, but designed so that it can be built more efficiently. One strength of the CK 12 was that the polar patterns were very precise throughout the frequency range, and this is not necessarily true with many large-diaphragm condenser microphones. The external dimensions of our new capsule are nearly identical to the original CK 12. The dimensions have a lot to do with the performance, and the CK 12 was very good in this regard. However, the CK 12 was very difficult to manufacture. There was a lot of mechanical work that could only be done by hand. Automated machines are very expensive and high-end microphone capsules are not manufactured in great enough quantities to justify the investment in automation.

Yes, I have read that about 2,500 AKG C 12 microphones were built during its ten-year run, so that would seem to be only about one mic per working day.

CF: Exactly. So we have come up with a capsule design that is very traditional in terms of acoustics, but we are mounting it together with new materials which makes assembly much faster. The new capsule uses a ceramic-on-ceramic interfacing of the capsule halves where most manufacturers use a metal-on-plastic interfacing. Ceramic has many advantages. It is stiffer and more temperature independent than the plastic rings. This is why we have only three screws that hold the halves together and lock the tension in place, whereas most capsules use many more screws. It also has a higher density, which improves mechanical isolation. Some of the critical parameters like membrane tuning are now partly automated. Our new design has much greater consistency, capsule-to-capsule, than was achievable with the original CK 12 capsule.

On the Austrian Audio website you have a paper on the CK 12 capsule and it suggests that the capsules were hand tuned at the factory, and this would require the capsules to be disassembled to change the thickness of the spacer rings and then reassembled.

CF: Yes, the spacing between the diaphragms and the backplates is critical to the microphone's polar response, as is the acoustic resistance between the capsule halves, which in the CK 12 was also partly determined by a spacer ring. With both the brass and plastic CK 12 capsules it was difficult to maintain these spacings precisely in the manufacturing process. A gap of 20 microns (.00079 inch) might give a cardioid pattern and a gap of 22 microns (.00087 inch) might result in a hyper-cardioid pattern. The CK 12 was known for its very consistent rear rejection of around 20 dB, but achieving this required hand tuning of each individual capsule. With our new capsule we have come up with a manufacturing process that allows this spacing to be much more precise. In fact, we have filed a patent on our new process. We are using automotive grade Swiss meshes for the acoustical resistance between the capsule halves, and it is very consistent so we don‘t need to tune each capsule individually.

The brass ring CK 12 capsule was assembled with multiple screws, but the later ULS series capsules were assembled without screws. In fact, I have read that they were glued and that this made the critical spacings you mention less consistent from capsule to capsule.

CF: Actually, the capsule for the 414 ULS series was pressed together with a plastic ring, not glued. This works well for the initial assembly, but is a problem if you need to do any kind of service. If you take it apart the plastic ring will be damaged such that it will not press back together tightly. Our new capsule is going to return to using screws, just not so many.

What can happen to a mic that the capsule might require service?

CF: The really old CK 12 capsule had trouble with the membrane material losing tension over many years. This can lead to problems like the membrane touching the backplate. So re-tensioning the membrane was the most common service need. It also had a problem with humidity. In the C 12 tube microphone the heat generated by the tube actually helped keep the diaphragm dried out and stabilized, but when they switched to the transistor version they started having more humidity problems with the old capsule. This is one of the reasons they switched to the plastic capsule. Actually, there is a lot of plastic in the original CK 12 capsule as well.

You make the mic diaphragms here?

CF: Yes, we buy the gold-sputtered mylar from a company in Germany that many mic manufacturers buy from. Then all of the tensioning and gluing is done here by hand.

What other products are you working on or hope to work on?

KI: We are looking at headphones; both in-ear and over-the-ear models. There will definitely be a high-end model in the plans, something along the lines of the AKG K872. We are quite interested in noise-cancelling headphones and have a lot of expertise in this area. We also hope to be a developer for manufacturers of Bluetooth, wireless, and noise-cancelling chips. They need products to be developed, like headphones, that use their chips so that they can sell more chips. Other areas of interest include small-diaphragm condenser mics and RF wireless.

Can you show me the new microphone?

KI: [laughs] Sorry, only the capsule at this time.

Are you interested in the consumer market?

KI: Yes, although most of the products we are working on right now are aimed at the professional audio market, we are interested in the industrial and consumer markets. We have a consumer product in development that unfortunately I cannot reveal at this time, but it is really cool!

CF: For professional products we do a lot of lifespan testing where products might be in the climate chamber for weeks. For automotive products you have to test across a wide range of temperature and humidity conditions. With our chamber we can try to simulate the entire life-cycle of the product in a compressed time frame. We have the climate chamber right next to the anechoic chamber so that we can bring products up or down to a certain temperature and then quickly move them into the anechoic chamber and measure their performance.

What audio products or components require the most climate testing?

CF: Dynamic speakers are the worst, because their materials are not so robust. Headphone drivers have a lot of plastic parts and glues.

Your anechoic chamber is impressive.

KI: Thank you! There is a funny story around it. The anechoic chamber that AKG had was in a rental building. It was one of the largest chambers in Europe at the time, but was in a building that was much larger than we needed for Austrian Audio. The owner of the building wanted to rent it to a new tenant but was, of course, not able to find a renter who wanted an anechoic chamber. Ultimately we were able to strike a deal with the owners and move the chamber to our current location. We finally completed the installation here in June of 2018.

CF: And this installation actually performs better than the one in the previous AKG location. In the old building the walls around the chamber were concrete, but here we were able to use two layers of drywall mounted on isolation plates, and this acts as a plate absorber down around 20 to 30 Hertz.

I see that the chamber has the needed huge ducts for HVAC.

CF: Yes, this part also came from the old AKG building. The large channels reduce the airspeed which reduces the noise.

Clearly Austrian Audio is an experienced startup built from an AKG foundation, but it takes a lot of capital to get a business like this going. How have you guys managed to finance it?

KI: Like anything in the audio industry, the best way to make a million dollars is to invest two million! The heavy lifting was all done by Martin Seidl, former Director of Sales at AKG and our CEO. As I said earlier, we had a lot of frustrated engineering talent. Once Samsung announced they would be closing AKG in Vienna we had no choice but to look for an alternative. Martin started calling people who might be willing to invest in an audio engineering company in Vienna, where we have the talent but costs are high. Thankfully Austrian law requires a generous severance package when a company is closed, so that helped us with the transition. Additionally, we have been able to generate some revenue by hiring out our engineering and consulting services to other companies.

When can we expect the new Austrian Audio condenser microphones to be available?

KI: Our first two microphones will debut at Frankfurt's Musikmesse in April of 2019 and will feature our newly developed "Open Acoustics Technology." It will be a large diaphragm, dual and true-condenser microphone, with a number of novel and inspirational new features and tools for the musician and engineer. Our first professional headphones will be unveiled at Musikmesse as well. Stay tuned and stop by to see the new products!