I recently stocked up on cables from Monoprice. I got ten 25 ft mic cables, twelve 10 ft 1/4'' male-to-male TS (mono) straight cables, and ten 8'' right-angle 1/4'' male-to-male TS jumper cables. For a previous review of high-end cables published in Tape Op, I did a blind-listening comparison with unknowing participants, and to my amazement, they were able to differentiate between two brands of cables in 8 out of 10 tests. The differences were subtle though - very subtle. The participants weren't 100% confident they could hear the difference until we compared their answers. So, while I understand that there's a benefit to high-end cable, I also know that cables are not the sonic bottleneck for most studios. In my case, I'd need much better sounding rooms before I start worrying about cable subtlety. I'd rather have cabling that is put together and soldered well - and will last. Up to this point, I've kept a stock of wire and connecters, and I'd make my own as needed. The Monoprice Premier Series cables are so inexpensive though, and high enough quality, that I won't be doing that anymore for standard cable types.

All of the connecters on these cables are gold plated. (STOP! Read the chapter on conductivity in Small Signal Audio Design by Douglas Self [Tape Op #90] before you argue about this.) Gold is highly resistant to corrosion, and it's a great choice for cable ends.

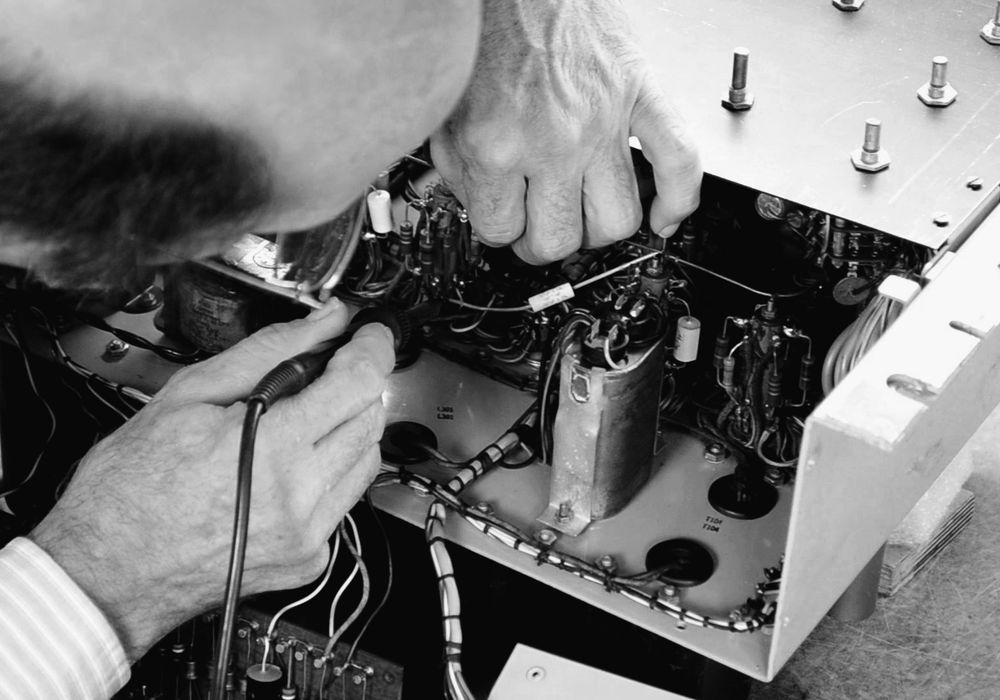

While trying to spot-check the solder joints on one of the straight Premier Series 1/4'' cables, I found that the inner connections were protected by a thick plastic mold - something I've not experienced before. It might make these a pain to repair if needed, but it looks like it will make them extra durable. Unlike other cables that are in the same price range, these have a metal-spring strain-relief to protect the cable from kinking at the connecter. The connecter body is a typical screw-on.

The 1/4'' angled cables have ends that unscrew like the straight cables', but then the back of the connecter comes off to reveal the solder joints. Each is protected by shrink tubing. The little bit of solder that showed through was shiny and clean. There is no plastic mold on the angled cables, and no spring relief. These look easy to repair.

The XLR cables have connecters that screw together with three small screws that are very visible. This gives them an industrial look that I did not like at first, but it grew on me. When removed, a small piece of the XLR case comes off. The strain-relief on this is rubber; it grips the wire jacket with pure friction and slots into a groove inside the XLR case. If you push the strain-relief down, you can push the cable pin assembly out and see the solder joints - clean and shiny. The ground wire is encased in not-shrunk shrink tubing. The ground pin is attached to the case-tab with just a few strands of plated wire. There is a plated wire lead coming up through the copper shield (I've only seen this before with foil-shielded cable), but both the copper and plated wire are soldered to the pin. The female connecter has a nicely shaped stub and button, and it clicks solidly into mics. It does not feel like there's a spring behind it though; I think just the tension of the metal is providing the spring action. (I could not get the female XLR connector fully disassembled as it is pressed together.)

Overall, I am really happy with the build quality on all of these, especially considering you can pay more for plastic- molded stuff. The angled 1/4'' jumpers are perfect for pedalboards. I might think twice before I used the XLRs for heavy gigging, but at these prices, you can carry spares, and they are a no-brainer for home studio use. Conversely, the straight 1/4'' cables look like they can take more abuse than most cables. (8'' Right Angle Male to Male $3.00 direct; 10 ft 1/4'' Male to Male $5.41; 25 ft XLR Male to XLR Female $11.56; www.monoprice.com)

_disp_horizontal_bw.jpg)