Sometimes not knowing what you're getting into is a good thing. I don't know what Rick Wilkinson was thinking when he decided to whip up a ribbon mic from scratch, but it's a good thing he's not easily deterred. A technical writer/corporate trainer by day, it only seemed natural for Rick to document his experience. And it's a good thing that he decided to share. In this 14-page (and growing) PDF, Rick provides step-by-step instructions on how to build your very own ribbon mic for around $150 in parts and materials. Since I had some experience assembling condenser mics, I figured I could build something with these plans in an afternoon. I thought I could buy some "ribbon capsules" and be cooking. (You can purchase almost any variation of prebuilt condenser capsules from a number of sources. I made the assumption that there was somebody doing a similar thing with ribbons. Oh, silly rabbit me. I can be such a ding dong.) Imagine my surprise as I read the pages where Rick demonstrated how to make your own ribbon element by hand. No, you don't have to smelt the aluminum, but you have to cut the leaf, crimp it, and mount it correctly. If you're envisioning kitchen-grade aluminum foil, you're wrong. We're talking about 0.6 micron leaf, which is significantly more fragile. I was reminded of what ribbon mic guru Clarence Kane told me (for an upcoming Behind the Gear), "I've been cutting ribbons for decades, and I still mess them up on occasion." I started to get scared.

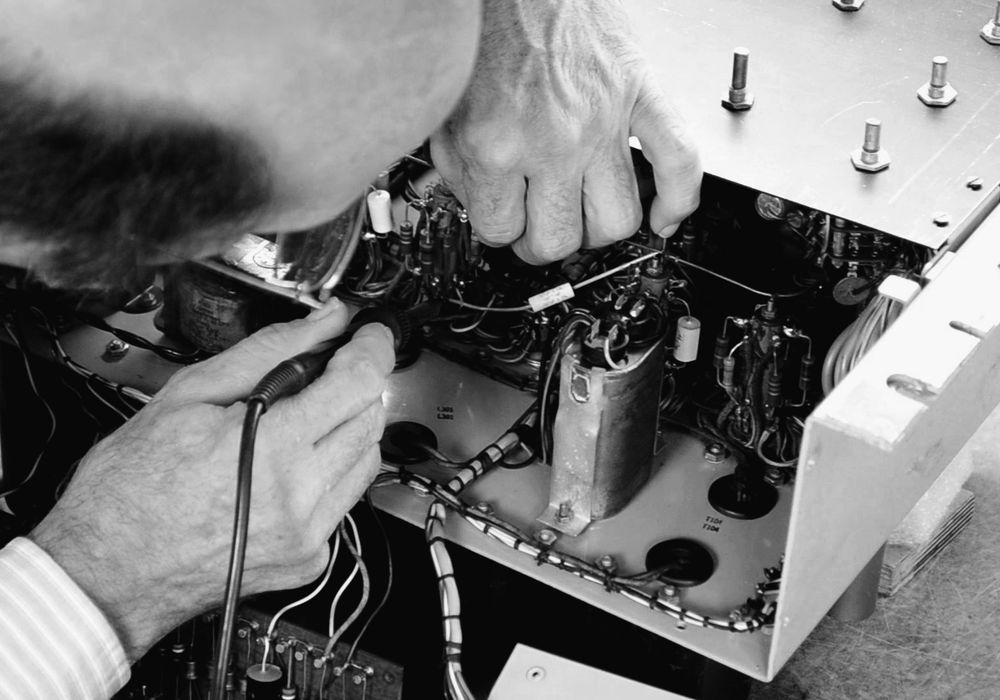

But don't let any of this deter you. The writing is clear and well supported by applicable photos and illustrations. The amount of precision soldering is at a minimum. In fact, if you have patience and a little bit of time, you have the skills to make a great mic of your own. As a great bonus, there is an appendix filled with hints and tips to help fledgling builders avoid mistakes that cost time and money. Don't skip that part.

The total cost for the first mic is about $150 for parts and shipping. This assumes you use an inexpensive transformer. However, the initial outlay includes enough brass handrail, plastic rod, aluminum leaf, epoxy, and screws to make another mic. So, depending on transformer costs, a stereo pair could be had for about $200. Not bad.

Speaking of transformers, there are different options, and the author includes this information, allowing builders to customize their mic to taste and budget. He also devotes a significant amount of attention to body and windscreen fabrication. Anyone familiar with DIY projects on the web can attest that many projects provide little, if any, guidance on this crucial section of mic construction. What are they thinking? Is the mic supposed to live on a breadboard forever? Notes on suppliers, prices, and contact information are provided to round out the section.

The author provided me with independent laboratory tests of two of his microphones. Both his large and small model showed outstanding accuracy, especially from the low mids to about 10 kHz. Samples posted on his website prove that this mic is a worthwhile investment. This thing is a solid recording tool.

If you have some time and patience and can afford a couple hundred dollars for materials, I encourage you to purchase a set of these plans and try your hand at ribbon mic building. Will your results be as good as a top-of-the-line Royer, Crowley & Tripp, or AEA? Probably not, but those are world-class tools. I still bet your mic could find daily use in your studio environment. And I'm very confident it will utterly smoke any of the bargain ribbons currently on the market. Just make sure you submit photos and sound samples to the ever growing collection at the author's site. I'll be sending mine in... as soon as I unglue my fingers. ($9.95 direct; www.rickshawrecords.com)

Tape Op is a bi-monthly magazine devoted to the art of record making.

_disp_horizontal_bw.jpg)