I could write 10,000 words about plate reverbs, modifications, reasons I feel these physical reverb units are unique sounding, and why I love the EMT [Elektro-Mess-Technik] 140 that I own. But the people who will need to know about this product either own an EMT 140 (and probably have the same feelings that I do) or are out looking for a vintage plate right now. Here's the story: Rick Perrotta, one of the principals at Royer Labs, bought his second EMT 140 plate reverb a while back and during transport the magnet assembly was lost. Now, in case you think one can pick up the phone and order spare parts, remember that these plates were manufactured many decades ago. So, being that Rick works at Royer and ribbon mics are nothing-but-dependent on magnets in order to function, he got together with friends at Advanced Theoretical Concepts, and designed a new magnet assembly for the ubiquitous EMT 140.

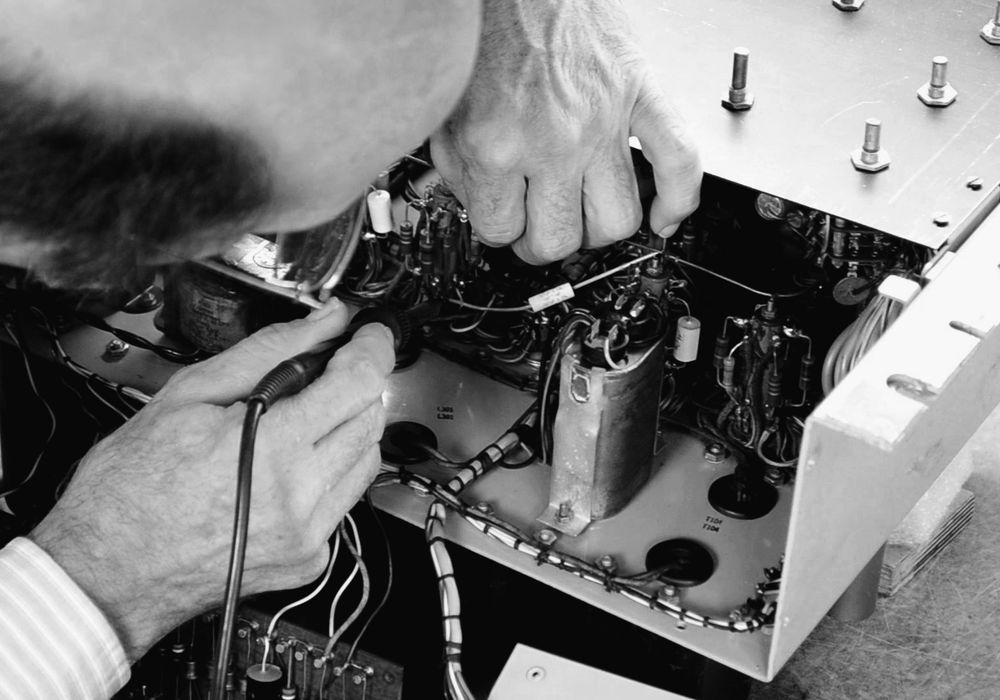

What arrived at Jackpot! Recording was a beautifully-constructed new part for my 140. Unlike the solid metal casing of the original assembly, the 140NM has a clear plastic ring where one can see the parts inside, with perfectly engineered metal casing and flange on the rest. It also comes with mounting screws and washers (if needed) and a custom alignment disc. Swapping out the assembly isn't technically that hard, but there is a certain process to opening up the wooden outer box on the plate and carefully removing the old magnet, as a wrong movement can destroy the drive coil that centers inside the magnet assembly. I bolted in the new 140NM and ran some tone tests (printing and recording tones through the plate into Pro Tools) to compare to the original's signal. When I realized the levels were lower, I had to change the alignment of the mount that the assembly is bolted to by removing some washers (using the alignment disc to keep it centered). With the drive coil slightly deeper within the magnet assembly I achieved levels matching my previous magnet, and much more balanced left/right frequency responses.

When I compared audio examples (to ones I'd previously printed with the old magnet assembly) I had to do some deep listening. These EMT 140 plates originally had tube or solid state electronics, and many people replaced them with Martech's retrofit assembly, but my EMT 140 has custom input and output electronics built by Hamptone, and I love the way it sounds. What I heard from the new magnet assembly – after a lot of A/B listening – was a certain amount of midrange definition that I had not been previously experiencing. High end was very similar to my old magnet, but now I felt a wide range of mids had gotten clearer sounding. I get the feeling my old assembly wasn't suffering from too much loss of magnetism, and Rick warns that some users may need to calibrate the I/O levels as the new magnet can increase the output voltage of the drive coil. I'm happy that I've increased audio fidelity of my 140, and I'm obviously not worried about having an unmodified vintage plate, although it'd be easy to swap the magnet assembly back out if someone wanted that! But I'm mostly excited that Rick has reverse engineered a new part for us with the EMT 140NM. I know there are others like me that will be excited as well, and I'm hoping this review serves as a notice to check in with Rick and pick one up!

$799; royerlabs.com/custom-shop

-LC

_disp_horizontal_bw.jpg)