I became acquainted with Glenn Coleman when we shared a week together at the Audio Engineering Society Convention (AES) in New York. Glenn's early employer, MCI, was a leading manufacturer of pro audio recording equipment from the '50s to the early '80s. Later he found work at Atlantic Studios and Martin Audio as well as founding his own Coleman Audio where he designs and manufactures top quality DAW monitor controllers, alternate speaker switchers, VU metering systems, surround level controls and surround switching modules. Coleman Audio gear is used by The Rolling Stones, Stevie Wonder, The Dave Matthews Band, Atlantic Recording Studios, Sony Music Studios, Bose Corporation, Microsoft, NBC, CBS, ESPN, Warner Bros and many other facilities, large and small.

I became acquainted with Glenn Coleman when we shared a week together at the Audio Engineering Society Convention (AES) in New York. Glenn's early employer, MCI, was a leading manufacturer of pro audio recording equipment from the '50s to the early '80s. Later he found work at Atlantic Studios and Martin Audio as well as founding his own Coleman Audio where he designs and manufactures top quality DAW monitor controllers, alternate speaker switchers, VU metering systems, surround level controls and surround switching modules. Coleman Audio gear is used by The Rolling Stones, Stevie Wonder, The Dave Matthews Band, Atlantic Recording Studios, Sony Music Studios, Bose Corporation, Microsoft, NBC, CBS, ESPN, Warner Bros and many other facilities, large and small.

How did you end up working on recording gear for MCI [Music Center Incorporated]?

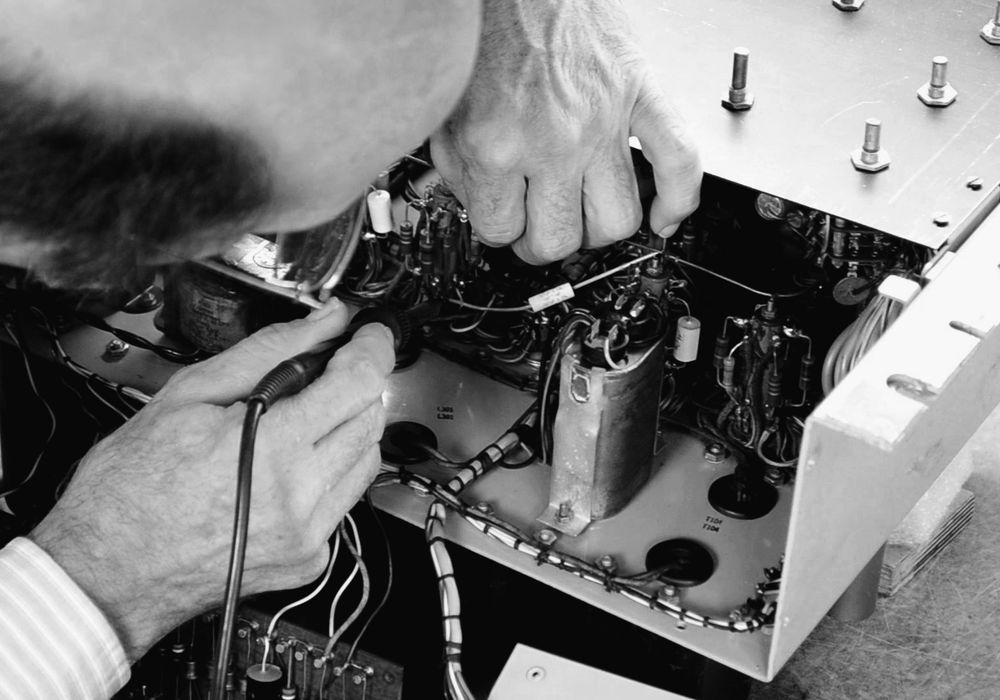

My pal Steve [Beverly] went over and applied at MCI. He had worked for a short time at Ampex, and because he had some experience they hired him right away. I got an interview, but they didn't hire me. But I'd already quit Motorola, I'd quit immediately, and it wasn't a smart move to make, no unemployment or anything else, I'd just quit. I then proceeded to try and get a job at MCI for the next eight months. Meanwhile, I was making ends meet by being a roadie in a rock band called Uranus. We were a glitter rock band at the height of the disco scene in South Florida. We were playing bars when we could get a gig, but we couldn't a gig south of Jacksonville. I did the sound and I was a roadie. I had the car, basically. That was where I started in live sound engineering. But I was still applying at MCI. The receptionist took my job application, once a week, for eight months, before MCI hired me. I think she was throwing my applications away. I found that out because when I did finally get hired, I'd gone in and filled out an application on Monday. I then saw an ad for electronics technicians at MCI in the paper on Tuesday, and went back Wednesday, only to find I needed to fill out an application again. This time they hired me. I started in 1974. MCI were still selling 16-tracks. I was put into the console check out department, and I worked for a guy named Wally Watkivs, who taught me a lot. We were doing the final test on brand new consoles that had never been working before. We made sure everything worked and took specs and packed them up. The console was called a JH-428, and its predecessor was a JH-416, which was a black version. The JH-416 was the first inline console on the market. Before that, recording consoles were split — inputs on the left side, outputs on the right side, making them twice as long as they should have been. Whenever MCI made enough changes that it was significant, they would change the color of a unit. This made it easy troubleshooting a problem on the phone. You would just ask the customer what color the unit was and then you knew the version. They were selling them to all the kinds of recording studios, around the world. We were one of three commercially popular manufacturers of the time, the others being Neve and Trident, both from England. But we made tape machines as well as consoles. Jeep [Jeep Harned, founder of MCI] started by going down to Criteria Recording Studios and he fixed up Mack Emerman's studio, and Mack said, "Hey, can you make some electronics for this tape deck over here, because this sounds horrible?" Jeep designed some audio electronics for a Scully tape deck, which improved the sound and reduced distortion. So then Mack told him, "If you build a tape deck, I'll buy it." Jeep went back and he and Jim Strickland designed the JH-10 16-track, which was the not the first multitrack on the market but it was the first one that MCI had built. It was the first tape deck to have a constant tension for tape handling. They sold them to Criteria, and then to Atlantic, because the two companies were closely affiliated at the time. Those were MCI's two major clients. Criteria was like home: we could take new products to them, to test out in the real world. As far as Atlantic, we had Tommy Dowd, who had been with the company practically from the beginning. Tommy had great input about what Atlantic needed in tape decks and consoles. Jeep always listened to the end user ideas. I try to keep that in mind when I talk to customers on the phone or at tradeshows. These are the people who have the needs that become tomorrow's new products. We also sold to Record Plant, A&R, RCA, Sigma Sound — a lot of New York studios. Some of that came later, when Ham Brosious and Audiotechniques started selling MCI. The tape decks that MCI competed against were Ampex, Studer and 3M. MCI could package the console, multitrack tape recorder, and the 2-tracks, all at the same time. We could sell everything that you needed in a package deal, making a better price and you had a studio.

Any memories of working with Jeep Harned?

I remember working in the console check out area at MCI one day. Consoles are big and you get down inside and you're looking for where the problem is, and you have your head down in there. There's a part called an electrolytic capacitor and it's got a polarity, so if you turn it around backwards from what it should be, it'll explode. Jeep had come in to talk to Wally and they were over in the corner. I have my head down in a console, and one of the modules had an electrolytic capacitor in backwards, and it exploded, which like a gunshot — BOOM! It sprays paper and gook all over, and was all in my hair. I jumped up and turned around and Jeep and Wally were rolling on the floor, laughing. Jeep had what I call "the recording engineer's touch." He would come into the checkout area walk up to a console that had a couple hundred switches on it and push the one switch that wouldn't light up the LED. I used to think he came in at night, and went up and down the whole thing, to find out which one wasn't working, because there's no way he could have known. But he did, and he did that more than one time.

Where did you travel for MCI?

In the beginning I was travelling domestically: New York, L.A. and Nashville to A&R, Atlantic, and a lot of other studios. The dealers had tech staff but they weren't intimate with the product. The dealers had a lot of lines, so when they had a problem that was out of their hands they would call the factory. The deal was, "You pay the expenses, we supply the labor" and I was the labor. One day the [MCI] service manager, John Shepard, came to me and said they were having some trouble in France. So off I went to the Honky Chateau, a very big client. I was at Château d'Hérouville, fixing the console when The Sweet were recording. They would come up after I had the console completely apart and say, "Can we get started?" I would say, "Give me 15 minutes." They would look at me like I was crazy because the whole desk was apart, but I had it back together for the session. I was there for a week while The Sweet were there. During that week, I was working at night and I would start about 11 pm or midnight, after they had recorded all day long. I would work until 8 or 9 am, until they wanted to start working again. There was a problem in the console. I could get it to work, but it wouldn't last, it would blow out. It was annoying and I was having a terrible time trying to figure it out. I was working one evening at the console, and the way the room was set up there was a rack of Dolby's [noise reduction] to the left, and behind that was where they kept the amplifiers for the speakers and the power supplies. It was a small room with a cubbyhole that you crawled into, like a trapdoor, but that door was in the studio, so the big window for the control room was in front of me. I don't know what time it started, but I started hearing what sounded like human heavy breathing from behind the Dolby rack. And it continued. And nobody had walked past me, because the control room window was right in front of me. No one had gone over to where you entered that amp room. I kind of just focused on working on the console, and I didn't look up. I didn't know what was going on, honestly. When the sun came up, it just stopped. It stopped way before anyone came up to ask about, "Can we get started?" or anything. I didn't say anything to anybody, because I thought it was a joke, and I thought somebody was going to come up to me and say, "Hey, did you hear the ghost last night?" But nobody said anything to me. And it never happened again, after that. It was only that one night. Honest to God. That was probably 1977 or 1978.

Who was buying all this recording gear?

We were selling to TV broadcasters. Houses of worship were big clients too. Anyone who needed to record something. But recording studios were the thing. I want to say we were shipping probably eight to ten consoles, maybe ten 24-tracks, and up to one 120 2-tracks every month. We were moving gear!

It's been said that at that time, one third of the albums on the Billboard top 100 were recorded on MCI equipment. Is that so?

MCI sold to Criteria, who did all the Crosby Stills Nash, Eric Clapton's 421 Ocean Boulevard, all the Lynyrd Skynyrd stuff, the Eagles' singles, Foreigner, Carly Simon, James Taylor and the list goes on. Criteria had everyone coming in. Later on, AC/DC, Queen and Led Zeppelin albums were recorded on MCI gear. Neil Young even had us make a small 4-channel version of the JH-528 to put on his boat.

Why did you move from MCI to Atlantic Studios?

I continued travelling to studios around the world for MCI. Then in the early '80s Sony bought MCI. Within a month or so I could see that I didn't like what was happening. During my many trips to Atlantic I had made friends with Sami Uckan who was the chief engineer at Atlantic Records. Sami had told me. "Anytime you want to get a job up here, just call me." I called him and said, "I'm ready to come up there and work." and he said he'd hire me. There was a service call scheduled for Atlantic and Sami told me, "Okay, tomorrow you're going to go in and talk to the studio manager Dave Tieg." But the next day Dave Tieg got fired. It was a shock, because nobody knew it was coming. I went back to Florida, and a new manager came into Atlantic, named Paul Sloman. After a month or so Paul and Sami came down to MCI. I met Paul and he said, "Yes, you're hired." Then Atlantic moved me to New York. I worked there at Atlantic, for about six or seven years as a staff tech in the shop. First thing in the morning we would align all the tape decks for all the sessions. They were using MCI and Studer 24-track decks. There were two in each room, so they were really 48-track setups. There was so much coming through the Atlantic Studios. Arif Mardin was the staff producer, who recorded the Rascals, Chaka Kahn, David Bowie and many others. Tommy Dowd came up, I met Tommy when his health was failing. He came up to talk to Ahmet [Ertegun] about getting some money for doing "Layla." He was in bad shape at the time, but it was really a honor to meet him. I also worked with Gene Paul, who is Les Paul's son. Gene was a staff engineer. Jimmy Douglass was another staff engineer at the time. They had done so many records at Atlantic. Roberta Flack, Foreigner, Aretha Franklin, David Bowie, The Bee Gees, George Benson and Neil Young — all these great artists were in the studios. Miles Davis was there before he died. You just can't imagine the people that went through there — the list just goes on and on. But I was the repair guy and we were striving to keep the studios from having any kind of down time, so there was always some kind of tech staff on duty. Then Paul left to go to A&M in California, and they brought in Tony O'Brien, an accountant, to run the studio — that was a disaster. He didn't book the studios and that ran things into the ground. But there's a funny story in there: It was the late '80s and CDs were coming out. The CD system that Sony sold consisted of a 1630 digital processor and two DMR 4000s, which were 3/4" video decks. The DMR 4000 was the workhorse of the system and it needed to be completely rebuilt every 1000 hours. Because it's a video deck, which has high tape tension, the heads wear and then you have to change all the parts. Well, nobody knew how to do that, and I wanted to learn. So I got in touch with Sony and got a brochure about training, which I took to Tony. I said, "If I go out to San Jose and learn this on a two week course, I can come back and save you a whole bunch of money in maintenance." And he said, "No. I don't want to do that." So, being like I am, and knowing how Tony was, an accountant who really wanted to work at Rockefeller Center and didn't want to work at the studio — I took the brochure, I put it in an envelope and wrote "Tony O'Brien" on the front of the envelope, and put that in the interoffice mail, going down to the Rock [Rockefeller Center]. It went down to the Rock, where they said, "Oh, Tony O'Brien, he's up at the studio." They put it back in the interoffice mail, and it came back to Tony from the Rock [Rockefeller Center]. Then Tony opened the envelop with the brochure, called me in and said, "You're going to go out to San Jose." So I went out there and learned how to do these decks. But then Tony wouldn't buy the test equipment I needed to do the job. Still, I now had the knowledge.

And then you went on to Martin Audio?

I left Atlantic and moved on to Martin Audio on 55th Street. They didn't have anyone who knew how to repair the 3/4" video decks I had learned earlier, but they had the test equipment. I didn't have the experience yet but Martin Audio could see a way to make money doing this work. So I went back to Atlantic, to their head engineer Bob Caputo, [now the VP of Adam Audio USA], and talked him into giving me a deck to work on at Martin. I started doing overhauls on the DMR 4000 decks. Later, after I had left Martin, I bought my own test equipment and started doing the overhaul on those decks for all the mastering studios in NYC — Masterdisk, Hit Factory, Atlantic, Sterling Sound, and in the end I even did Sony Music.

Were you dealing with a broader variety of product?

Well, Martin Audio was a dealer and sold a lot of lines, such as Otari tape machines and Amek consoles. I had moved from MCI, which was just one product line, to Atlantic where I learned other products, but still just the major pieces, like the Studer tape deck or the SSL console. Then I went on to Martin Audio and was dealing with the Otari 24-tracks, Amek consoles and Tascam DATS and cassette lines and compressor limiters and all kinds of gadgets I'd never worked on before.

_disp_horizontal_bw.jpg)